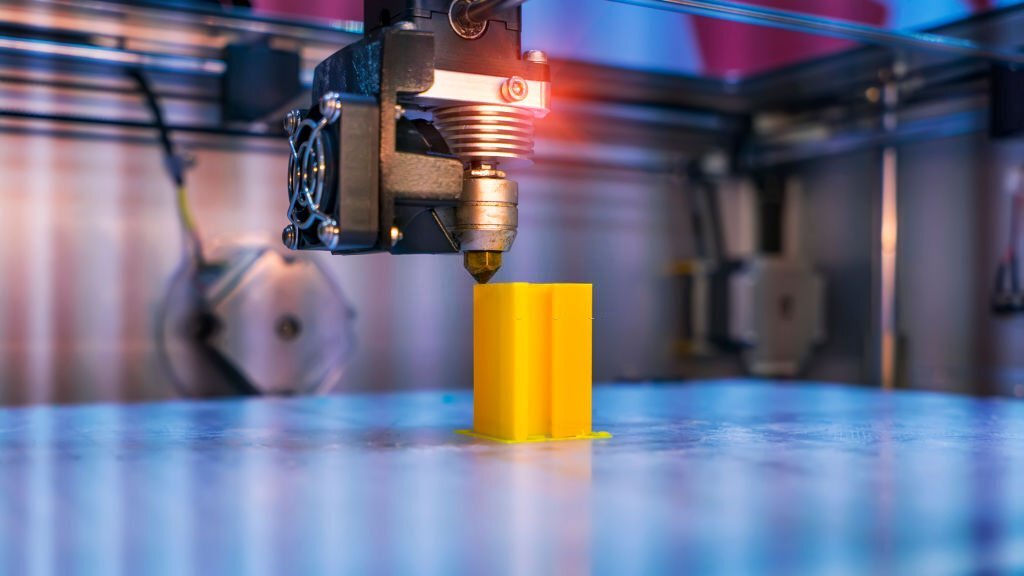

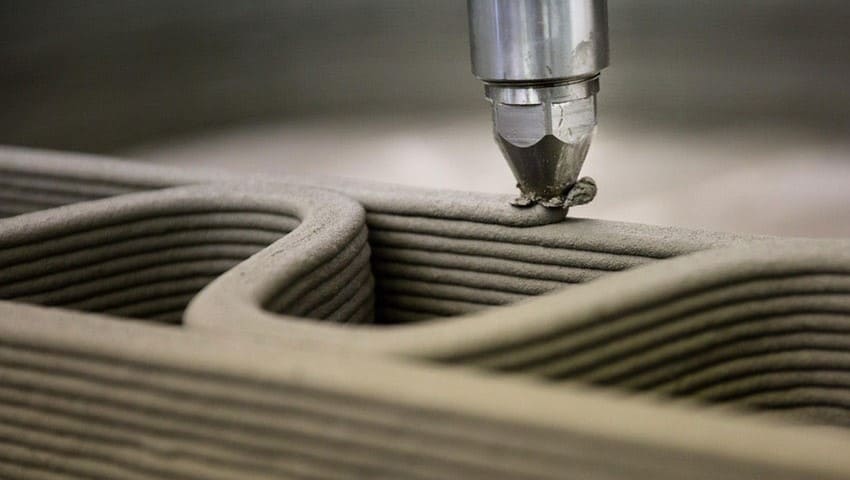

3D Printing is a process of layer by layer manufacturing in which the material is deposited through a nozzle/hopper/recoater with a predefined thickness of layer.

Concrete Printing have been in research since 1995 using sand and ceramic as the raw material

This technology has scaled up from 2000s to meet the demands of concrete printing using 'off the shelf' components (concretepumping, spray concrete, gantry system).

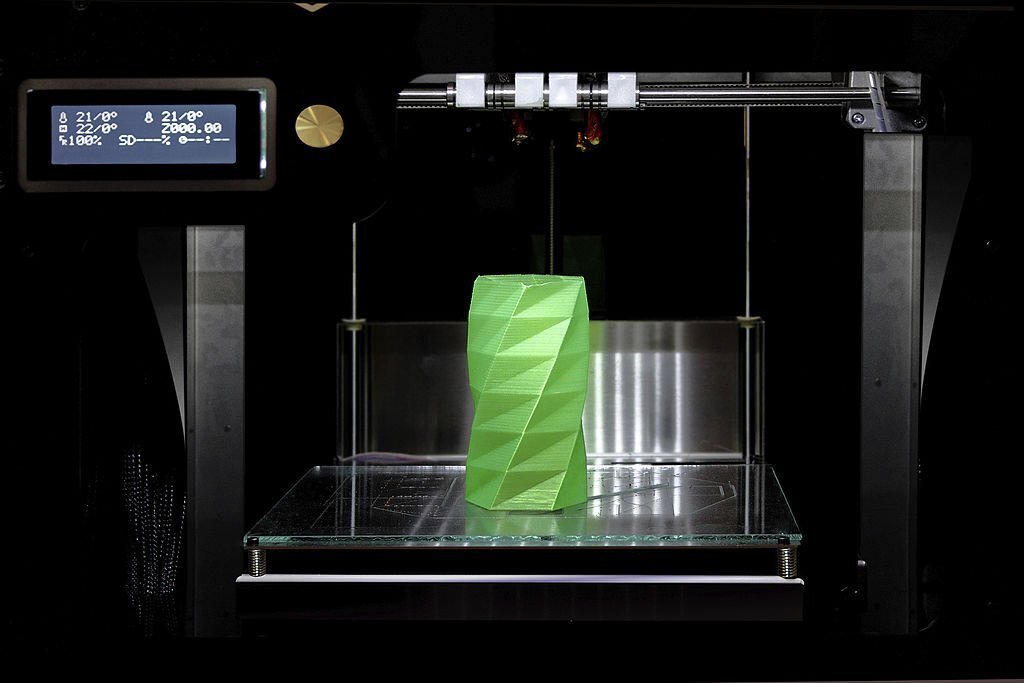

3D printing is revolutionizing the world in many ways. We focus upon construction of single to four story buildings and structures to save time, resources, labor, and overall cost

The construction industry seeks sustainable growth and development as the world witness transformation to Industry 4.0. The inventions in the conventional process of building, sculptures, artifacts, etc have pushed the boundaries for innovative thinking.

3D Printing has allowed designers/architects to design and create futuristic buildings, spaces, and articles.

Some of the major areas which can be benefitted from 3D Printing are listed below

Techniques and materials currently used in the construction industry has stagnated over the past several decades. In parallel, persistent demand for construction services, infrastructure buildouts, affordable housing and new developments continue to grow annually. Supply chain challenges have gone from cyclical to constant, and a dwindling workforce brings additional challenges to completing projects on time or in budget.

3D construction printers can help address such challenges with technology, automation, and innovative materials capable of kickstarting the evolution of the construction industry.

Although 3D printing itself is more cost-effective when building, the necessary machinery continues to be very expensive both to acquire and to operate it.

More regulations and legislation are needed for 3D printing in construction that allows for clear guidelines on its use and benefits of its implementation in new construction sites.